Guide to Buying Used CNC Equipment

Finding a used CNC machine for sale can save your business thousands while getting the precision equ...

Read More CNC machinery

CNC machinery

Author: Matt Spiller | 13 August 2025

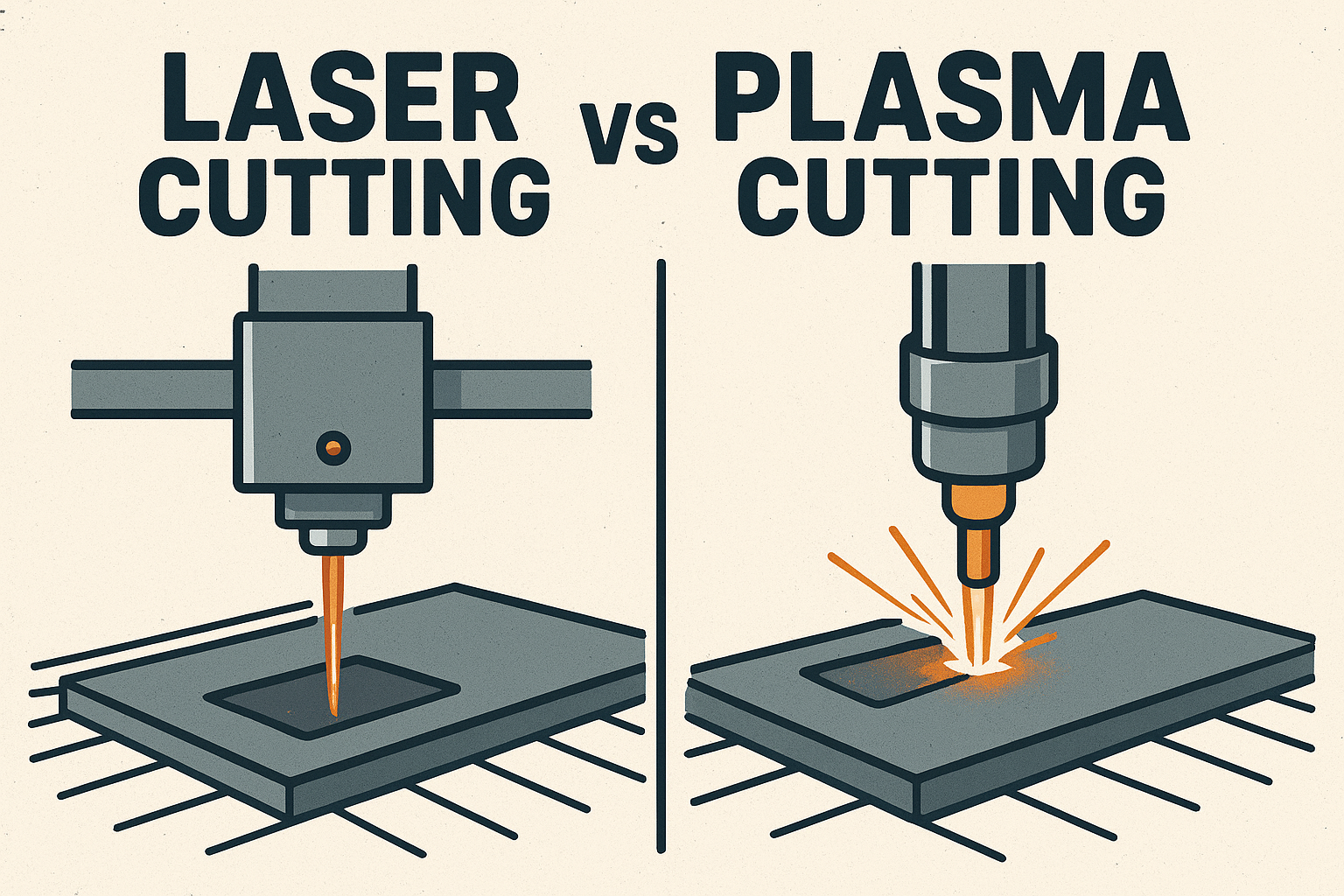

When it comes to cutting metal with precision and speed, two technologies stand out: laser cutting and plasma cutting. Whether you're purchasing a machine through a fabrication equipment auction or upgrading your in-house capabilities, understanding the differences between these two methods is essential to making the right investment.

In this guide, we break down how each works, their pros and cons, and which application suits your shop best.

Laser cutting uses a high-powered laser beam to cut through materials with extreme precision. It's commonly used on sheet metal, stainless steel, and thinner materials.

💡 If you're in the market for a fiber laser machine or CO₂ laser cutter, check for models from trusted brands like Trumpf, Amada, or Mazak in upcoming machine tool auctions.

Plasma cutting uses an electrically conductive gas to cut through metal. It’s widely used in heavy-duty fabrication and industrial manufacturing for its speed and versatility.

💡 Looking for a cost-effective cutting solution? Plasma cutting machines often appear in metalworking auctions and offer solid performance for job shops focused on throughput over ultra-high precision.

|

Shop Need |

Best Fit |

|

Thin, clean metal cutting |

Laser |

|

Intricate design work |

Laser |

|

Fast cuts on thick steel |

Plasma |

|

Budget-conscious buying |

Plasma |

|

Fabrication with rough materials |

Plasma |

|

Fine finishing & low distortion |

Laser |

|

Shop Need |

Best Fit |

|

Thin, clean metal cutting |

Laser |

|

Intricate design work |

Laser |

|

Fast cuts on thick steel |

Plasma |

|

Budget-conscious buying |

Plasma |

|

Fabrication with rough materials |

Plasma |

|

Fine finishing & low distortion |

Laser |

If your priority is high precision and minimal finishing work, laser is the clear winner. But if you're cutting thicker material and want speed on a budget, plasma will get the job done.

At Machine Tool Bids, we offer a wide selection of both laser cutting machines and plasma cutters through our live CNC machinery auctions and direct listings. You can find quality used fabrication equipment from top manufacturers—without the middleman.

👉 Explore our latest auctions to find the right cutting solution for your operation.

Bid smart. Cut clean. Save big.